Journal of Bionic Engineering (2024) 21:938–952 https://doi.org/10.1007/s42235-024-00482-x

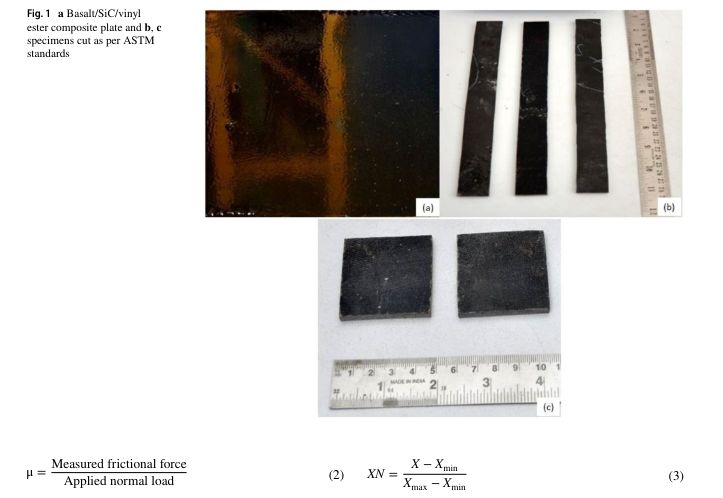

Modelling and Characterization of Basalt/Vinyl Ester/SiC Micro? and Nano?hybrid Biocomposites Properties Using Novel ANN–GA Approach

Yesudhasan Thooyavan1 · Lakshmi Annamali Kumaraswamidhas1 · Robinson Dhas Edwin Raj2 · Joseph Selvi Binoj3 · Bright Brailson Mansingh4 · Antony Sagai Francis Britto5 · Alamry Ali6

1 Department of Mechanical Engineering, Indian Institute of Technology Dhanbad (ISM), Dhanbad, Jharkhand 826004, India 2 Gati Shakti Vishwavidyalaya (GSV-A Central University Funded By GoI in the Ministry of Railways), Lalbaug, Vadodara, Gujarat 390004, India 3 Institute of Mechanical Engineering, Saveetha School of Engineering, Saveetha Institute of Medical and Technical Sciences (SIMATS), Saveetha University, Chennai, Tamilnadu 602105, India 4 Metal Joining Research Centre, Department of Mechanical Engineering, Sri Ramakrishna Engineering College, Coimbatore, Tamilnadu 641022, India 5 Department of Mechanical Engineering, Rohini College of Engineering and Technology, Palkulam, Tamil Nadu 629401, India 6 Department of Mechanical Engineering, College of Engineering in Al-Kharj, Prince Sattam Bin Abdulaziz University, 11942 Al-Kharj, Saudi Arabia

AbstractBasalt fber reinforcement in polymer matrix composites is becoming more and more popular because of its environmental friendliness and mechanical qualities that are comparable to those of synthetic fbers. Basalt fber strengthened vinyl ester matrix polymeric composite with fller addition of nano- and micro-sized silicon carbide (SiC) element spanning from 2 weight percent to 10 weight percent was studied for its mechanical and wear properties. The application of Artifcial Neural Network (ANN) to correlate the fller addition composition for optimum mechanical properties is required due to the non-linear mechanical and tribological features of composites. The stufng blend and composition of the composite are optimized using the hybrid model and Genetic Algorithm (GA) to maximize the mechanical and wear-resistant properties. The predicted and tested ANN–GA optimal values obtained for the composite combination had a tensile, fexural, impact resilience, hardness and wear properties of 202.93 MPa, 501.67 MPa, 3.460 J/s, 43 HV and 0.196 g, respectively, for its optimum combination of fller and reinforcement. It can be noted that the nano-sized SiC fller particle enhances most of the properties of the composite which diversifes its applications. The predicted mechanical and wear values of the developed ANN–GA model were in closer agreement with the experimental values which validate the model.

Keywords Hybrid polymer composite · Prediction · Process modelling · Artifcial neural networks · Genetic algorithm

Copyright © 2025 International Society of Bionic Engineering All Rights Reserved

吉ICP备11002416号-1